In addition to regulating chip breaking, implementing coolant controls tool temperature for a long and predictable tool life, while also offering positive effects on surface quality.ĭue to the benefits of using precision coolant, many of Sandvik Coromant’s tools for steel turning applications feature a degree of cooling technology. As such, turning tools that feature nozzles to deliver precision coolant to the cutting zone can control chip breaking and offer secure machining.

Operations like steel turning create a high-pressure environment for metal cutting tools. Coromant Capto® quick change tool holders for the T-Max® P carbide turning insert now include through-tool delivery of precision over and under coolant. With this addition, the new holders increase tool life and boost productivity.

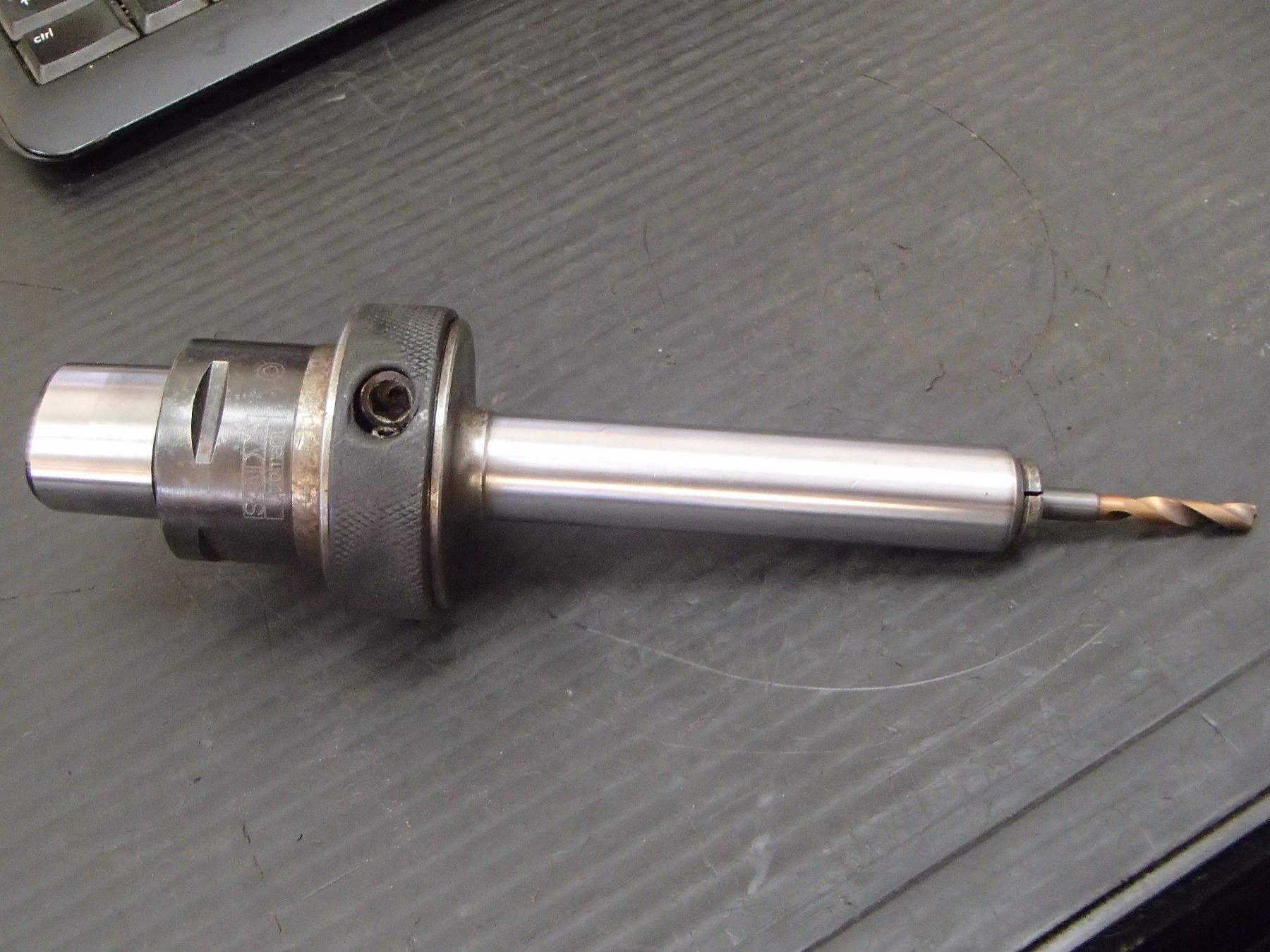

#SANDVIK CAPTO TOOLING ISO#

Precision coolant is especially advantageous for machining ISO S, M and P workpiece materials.

The Sandvik Coromant’s Coromant Capto® quick change tool holders for the T-Max® P carbide turning insert now include through-tool delivery of precision over and under coolant. Sandvik Coromant (Mebane, NC) has upgraded its long-standing tool family with precision coolant technology. Increasing Tool Life with Precision Cooling Lubricants, Coolants, Metalworking FluidsĬut back on the tooling process with versatile, flexible and innovative designs built into products that result in longer tool life and gains in your shop’s productivity.Computerized Maintenance Management Systems.Abrasives, Belts, Brushes, Grinding Wheels.

0 kommentar(er)

0 kommentar(er)